Hastelloy C-22 - Complete Material Specifications & Properties

Hastelloy C-22 is a high-performance nickel-based alloy renowned for its exceptional resistance to a wide variety of corrosive environments including chloride-rich media, oxidizing and reducing acids, and high-temperature conditions.

It is widely used in chemical processing, waste treatment, and marine applications where both durability and corrosion resistance are critical.

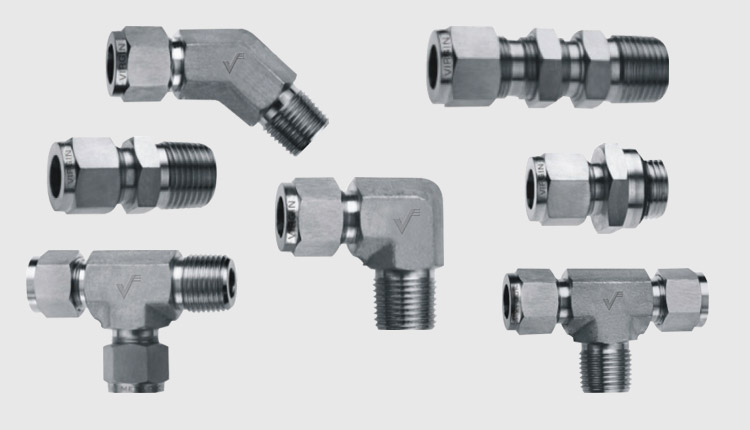

We supply these high-performance alloys in various forms including sheets, plates, pipes, tubes, bars, and custom fabricated components to meet specific industry requirements.

Each product undergoes rigorous quality testing to ensure compliance with international standards.

Abhinav Overseas is a leading supplier of Hastelloy C-22, providing premium quality materials with comprehensive certification and technical support.

Chemical Composition

| Element | Composition |

|---|---|

| Nickel | 55-63% |

| Chromium | 19-22% |

| Molybdenum | 13-16% |

| Tungsten | 2.5-3.5% |

| Iron | 3-5% |

| MinorElements | Trace amounts of manganese, silicon, carbon, etc. |

Material Properties

Mechanical Properties

- tensile Strength:≈620 MPa

- yield Strength:≈275 MPa

- elongation:≈40%

- hardness:Approx. HRB 90

Key Features

- Outstanding resistance to pitting, crevice corrosion, and stress corrosion cracking

- Excellent performance in aggressive chemical environments

- High strength combined with superior corrosion resistance

- Effective in both high-temperature and highly corrosive applications

Common Applications

- Chemical processing equipment

- Waste treatment systems

- Marine components

- Heat exchangers and pressure vessels

- Flue gas desulfurization systems

Standards

Additional Information

Engineered for reliability in the most demanding service conditions, Hastelloy C-22 is the material of choice when both high mechanical performance and exceptional corrosion resistance are required. Its versatility and proven track record make it ideal for a broad range of industrial applications.

Products Available in Hastelloy C-22

Products

Main Categories

Material Types

- Stainless Steel

- Inconel

- Incoloy

- Hastelloy

- Nickel Alloy

- Monel

- Titanium

- Cupro Nickel

Nickel Alloys

Standard nickel-based alloy compositions

| Material type | Ni | Cr | Co | Mo | W | Fe | Al | Ti | Cu | Nb | Other |

|---|---|---|---|---|---|---|---|---|---|---|---|

| - | - | - | - | - | - | - | - | - | - | - | - |

| Hastelloy A | 57.00 | 1.0* | - | 21.00 | - | 19.00 | - | - | - | - | - |

| Hastelloy B | 62.00 | 1.0* | 2.5* | 28.00 | - | 5.50 | - | - | - | - | 0.4% V |

| Hastelloy D | 85.00 | 1.0* | - | - | - | 1.0* | - | - | 4.0* | - | 9% Si |

| Hastelloy F | 45.00 | 22.00 | 2.5* | 6.00 | 1.0* | 18.00 | - | - | - | 2.00 | - |

| Hastelloy G | 44.00 | 22.00 | - | 6.50 | 1.0* | 20.00 | - | - | 2.00 | 2.00 | - |

| Hastelloy N | 72.00 | 7.00 | 0.20 | 16.50 | 0.50 | 5.0* | 0.25 | 0.25 | - | - | 0.01% B |

| Hastelloy R | 66.00 | 15.50 | 1.5* | 5.00 | - | 7.0* | 2.20 | 2.50 | - | - | - |

| Hastelloy S | 68.00 | 15.50 | - | 14.50 | - | 1.00 | - | - | - | - | 0.5%Mn 0.4% Si |

| Hastelloy W | 63.00 | 5.00 | 2.5* | 24.50 | - | 5.50 | - | - | - | - | 0.6% V |

| Hastelloy X | 47.00 | 22.00 | 1.50 | 9.00 | 0.60 | 18.50 | - | - | - | - | - |

| Hastelloy C276 | 56.00 | 16.00 | 2.5* | 17.00 | 4.00 | 5.50 | 0.4* | - | - | - | 0.35% V |

| Hastelloy C22 | 54.00 | 21.00 | 2.5* | 14.00 | 3.00 | 5.0* | 0.4* | - | - | - | 0.35% v |

| Hastelloy C4 | 54.00 | 16.00 | 1.25* | 16.00 | - | 2.0* | 0.4* | 0.5* | - | - | - |

| Inconel 600 | 75.50 | 15.50 | - | - | - | 7.00 | - | - | - | - | - |

| Inconel 601 | 60.50 | 23.00 | - | - | - | 14.10 | 1.35 | - | - | - | - |

| Inconel 702 | 79.00 | 15.60 | - | - | - | 0.40 | 3.40 | 0.70 | - | - | - |

| Inconel 713C | 72.00 | 13.40 | - | 4.50 | - | 1.5* | 6.20 | 1.0* | - | 2.30 | - |

| Inconel 718 | 53.00 | 18.50 | - | 3.00 | - | 18.00 | - | 0.80 | - | 5.00 | - |

| Inconel 800 | 32.00 | 20.00 | - | - | - | 47.00 | - | - | - | - | - |

| Inconel 825 | 40.00 | 21.00 | - | 3.00 | - | 32.00 | - | 1.00 | 2.00 | - | - |

| Inconel 901 | 42.00 | 12.50 | 1.0* | 5.70 | - | 35.00 | 0.35* | 2.90 | - | - | - |

| Inconel 792 | 61.00 | 12.50 | 9.00 | 2.00 | 3.90 | - | 3.20 | 4.20 | - | - | 4.2% Ta/ 1% Hf |

| Inconel 738 | 61.00 | 16.00 | 8.50 | 1.75 | 2.60 | 0.50 | 3.40 | 3.40 | - | 0.90 | 1.75% Ta |

| Inconel 939 | 48.00 | 22.40 | 19.00 | - | 2.00 | - | 1.90 | 3.70 | - | 1.00 | 1.4% Ta |

| GMR 235 | 63.00 | 15.50 | - | 3.20 | - | 10.00 | 3.70 | 2.00 | - | - | 0.06% B |

| Nimonic 75 | 77.00 | 20.00 | - | - | - | 5.0* | 0.15 | 0.40 | - | - | - |

| Nimonic 80 | 74.00 | 20.00 | 2.0* | - | - | 1.5* | 1.30 | 2.20 | - | - | - |

| Nimonic 81 | 65.00 | 30.00 | - | - | - | 1.0* | 1.00 | 1.75 | - | - | - |

| Nimonic 90 | 57.00 | 20.00 | 16.00 | - | - | 5.0* | 1.50 | 2.50 | - | - | - |

| Nimonic 91 | 47.50 | 28.50 | 20.00 | - | - | - | 1.20 | 2.30 | - | - | - |

| Nimonic 105 | 53.00 | 15.00 | 20.00 | 5.00 | - | 1.0* | 4.70 | 1.20 | - | - | - |

| Nimonic 115 | 57.00 | 15.00 | 15.00 | 3.50 | - | 1.0* | 5.00 | 4.00 | - | - | - |

| Nimonic C263 | 50.00 | 20.00 | 20.00 | 5.90 | - | 0.75* | 0.50 | 2.20 | - | - | - |

| Nimonic C1023 | 56.00 | 15.50 | 9.50 | 8.00 | - | 0.25 | 4.30 | 3.60 | - | - | - |

| GTD 111 | 59.00 | 14.00 | 9.50 | 1.50 | 3.80 | 0.5* | 3.00 | 4.90 | - | - | 2.8% Ta/ 0.02*% B |

| GTD 222 | 50.00 | 22.50 | 19.00 | - | 2.00 | 0.25* | 1.20 | 2.30 | - | 0.80 | 1.0% Ta |

| Rene 41 | 52.00 | 19.00 | 11.00 | 10.00 | - | 5.0* | 1.60 | 3.20 | - | - | - |

| Rene 77 (Udimet 700) | 52.00 | 15.00 | 15.00 | 4.00 | - | 0.5* | 4.20 | 3.50 | - | - | 0.02*% B |

| Rene 80 | 60.00 | 14.00 | 9.50 | 4.00 | 4.00 | - | 3.00 | 5.00 | - | - | - |

| Rene 88 | 55.00 | 16.00 | 13.00 | 4.00 | 4.00 | 0.25 | 2.10 | 3.75 | - | 0.70 | 0.02% B |

| Rene 125 | 59.00 | 9.00 | 10.00 | 2.00 | - | - | 4.80 | 2.60 | - | - | 3.8% Ta/ 1.6% Hf / 7% W |

| Waspalloy | 56.00 | 19.00 | 14.00 | 4.20 | - | 1.5* | 1.40 | 3.00 | - | - | 0.1% Zr |

| Udimet 500 | 53.00 | 17.50 | 16.50 | 4.00 | - | 4.00 | 2.90 | 3.90 | - | - | 0.01 B |

| Udimet 520 | 56.00 | 19.00 | 12.00 | 6.00 | 1.00 | 1.00 | 2.00 | 3.00 | - | - | - |

| Udimet 600 | 52.00 | 17.50 | 16.50 | 4.00 | - | 4.0* | 4.20 | 2.90 | - | - | 0.04*% B |

| Mar M 246 | 600.00 | 9.00 | 10.00 | 2.50 | 10.00 | 0.15 | 5.50 | 1.50 | - | - | 1.5% Ta |

| PWA 663 (B1900) | 64.00 | 8.00 | 10.00 | 6.00 | - | - | 6.00 | 1.00 | - | - | 1% Zr/ 4% Ta |

| Mar M 200 | 60.00 | 9.00 | 10.00 | - | 12.00 | - | 5.00 | 2.00 | - | 1.00 | 0.12% B |

| Mar M 002 | 59.00 | 10.00 | 10.00 | - | 10.00 | 1.0* | 5.00 | 1.50 | - | - | 2.5% Ta / 1.5% Hf |

| Mar M 247 | 58.00 | 8.50 | 10.00 | 0.60 | 10.00 | 0.5* | 5.50 | 1.00 | - | - | 3% Ta |

| Alloy 230 | 57.5 | 22.00 | - | 2.00 | 14.00 | 3 | 0.30 | - | - | - | 0.1% C/0.5% Mn/0.4% Si |

| Kovar | 29 | - | 17 | - | 54 | - | - | - | - | - | - |

| N155 (Multimet) | 20 | 21 | 20 | 3 | 2.5 | 30.35 | - | - | - | - | 0.5% C/ Ta 1%/ Si 0.5% |

Need Hastelloy C-22 Products?

Contact our experts today to discuss your specific requirements and get a customized quote for your project.