Monel 400 / K500 - Complete Material Specifications & Properties

Monel 400 is a nickel–copper alloy renowned for its excellent corrosion resistance, especially in seawater and acidic environments. Monel K500 is a precipitation-hardened version of Monel 400, offering significantly improved mechanical strength while retaining similar corrosion resistance.

Abhinav Overseas is a leading supplier and manufacturer of premium quality Monel 400 and K500 alloys in India. With decades of experience in specialty metals, we provide high-performance nickel-copper alloys that meet the most demanding industrial requirements.

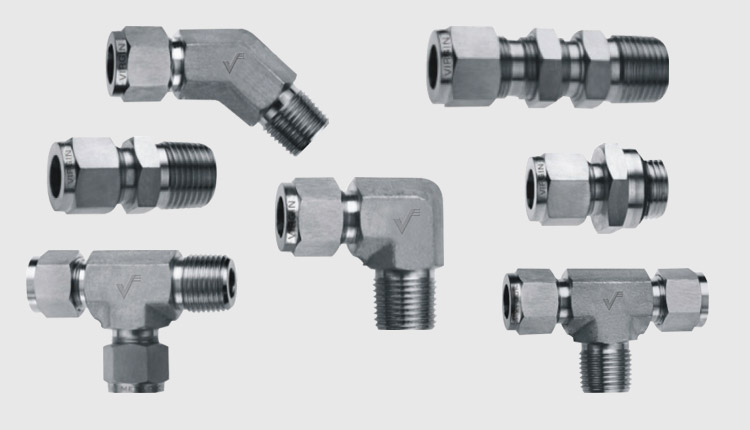

We supply these high-performance alloys in various forms including sheets, plates, pipes, tubes, bars, and custom fabricated components to meet specific industry requirements. Each product undergoes rigorous quality testing to ensure compliance with international standards.

Our Monel products are widely used in marine, chemical processing, oil & gas, aerospace, and high-performance industrial applications where exceptional corrosion resistance and mechanical properties are essential.

At Abhinav Overseas, we maintain extensive inventory of Monel alloys in various dimensions and specifications, ensuring prompt delivery and competitive pricing for both standard and custom orders.

Key Features

- Outstanding corrosion resistance in harsh and marine environments

- High durability and reliability for both standard and high-strength applications

- Versatile performance for industrial, chemical, and marine applications

Chemical Composition

| Element | Composition |

|---|---|

| Nickel | ≈63% |

| Copper | ≈28-34% |

| Iron | ≈2.5-3.5% |

| Manganese | ≈0.5-1.0% |

| Silicon | ≤1.0% |

| Carbon | Trace |

| Others | Trace amounts of impurities |

Material Variants

Monel 400 Stainless Steel

Carbon Content:

Mechanical Properties

- tensile Strength:≈485-620 MPa

- yield Strength:≈215-310 MPa

- elongation:≈30-40%

- hardness:Approx. HRB 90

Key Features

- Excellent resistance to corrosion in marine and acidic environments

- Good weldability and formability

- Non-magnetic in the annealed condition

Common Applications

- Marine components and seawater equipment

- Chemical processing equipment

- Heat exchangers, pumps, and valves

Standards

Monel K500 Stainless Steel

Carbon Content:

Mechanical Properties

- tensile Strength:≈860-950 MPa

- yield Strength:≈620-690 MPa

- elongation:≈15-20%

- hardness:Higher than Monel 400, approx. HRC 25-30

Key Features

- Precipitation hardened for significantly improved strength

- Retains excellent corrosion resistance similar to Monel 400

- Enhanced performance in high-stress and high-pressure environments

Common Applications

- High-performance marine and offshore components

- Aerospace structural parts

- Oil & gas and chemical processing equipment requiring high strength

Standards

Products Available in Monel 400 / K500

Products

Main Categories

Material Types

- Stainless Steel

- Inconel

- Incoloy

- Hastelloy

- Nickel Alloy

- Monel

- Titanium

- Cupro Nickel

Monel Alloys

Standard Monel alloy compositions

| Grade | UNS | Ni % | Cu % | Fe % | Mn % | C % | Si % | S % | Others |

|---|---|---|---|---|---|---|---|---|---|

| Monel 400 | N04400 | 63.0 min | 28.0-34.0 | 2.5 max | 2.0 max | 0.3 max | 0.5 max | 0.024 max | Al: 0.5 max, Ti: 0.5 max |

| Monel K-500 | N05500 | 63.0 min | 27.0-33.0 | 2.0 max | 1.5 max | 0.25 max | 0.5 max | 0.01 max | Al: 2.3-3.15, Ti: 0.35-0.85 |

| Monel R-405 | N04405 | 63.0 min | 28.0-34.0 | 2.5 max | 2.0 max | 0.3 max | 0.5 max | 0.025-0.060 | Added sulfur for machinability |

| Monel 401 | N04401 | 41.0-46.0 | 49.0-53.0 | 1.0 max | 1.0 max | 0.15 max | 0.25 max | 0.015 max | Used in electrical applications |

| Monel 404 | N04404 | 52.0-57.0 | Remainder | 0.5 max | 0.1 max | 0.15 max | 0.1 max | 0.025 max | Low magnetic permeability |

| Monel 450 | N04450 | 63.0 min | 28.0-34.0 | 2.5 max | 1.5 max | 0.15 max | 0.5 max | 0.015 max | Improved weldability vs. Monel 400 |

Need Monel 400 / K500 Products?

Contact our experts today to discuss your specific requirements and get a customized quote for your project.