317/317L Stainless Steel - Complete Material Specifications & Properties

Stainless Steel 317 and 317L are high-alloy austenitic stainless steels engineered for harsh and acidic environments. They offer enhanced resistance to chloride pitting, crevice corrosion, and stress corrosion cracking, thanks to higher molybdenum and nickel levels. The primary difference is the carbon content—317L has a lower carbon level, which improves weldability and minimizes the risk of carbide precipitation in welded structures.

Abhinav Overseas is a leading manufacturer and supplier of premium quality 317/317L stainless steel products in India. With decades of experience in the metal industry, we provide meticulously crafted products that meet the most demanding specifications for corrosion resistance and mechanical performance.

We supply these high-performance alloys in various forms including sheets, plates, pipes, tubes, bars, and custom fabricated components to meet specific industry requirements. Each product undergoes rigorous quality testing to ensure compliance with international standards.

Our 317/317L stainless steel products are widely used in chemical processing, pulp and paper manufacturing, pharmaceutical production, and marine applications where exceptional corrosion resistance is essential.

As a trusted name in the metal industry, Abhinav Overseas offers competitive pricing, prompt delivery schedules, and exceptional customer service. Our technical experts are available to assist you in selecting the right material specifications for your specific application needs.

Key Features

- Excellent corrosion resistance in acidic and chloride-rich environments

- Superior high-temperature performance

- Robust mechanical strength and durability

- Ideal for applications where pitting, crevice corrosion, and stress corrosion cracking are concerns

Chemical Composition

| Element | Composition |

|---|---|

| chromium | 24-26% |

| nickel | 11-15% |

| molybdenum | 3-4% |

| manganese | ≤2.0% |

| silicon | ≤1.0% |

| phosphorus | ≤0.045% |

| sulfur | ≤0.03% |

| nitrogen | Trace |

| iron | Balance |

Material Variants

317 Stainless Steel

Carbon Content: ≤ 0.15%

Mechanical Properties

- tensile Strength:≈520 MPa

- yield Strength:≈205 MPa

- elongation:≈40%

- hardness:Approx. HRB 92

Key Features

- Enhanced resistance to chloride pitting and crevice corrosion

- Superior performance in high-temperature and acidic environments

- Maintains strength and durability under severe conditions

Common Applications

- Chemical processing equipment

- Heat exchangers in aggressive environments

- Marine and offshore structures

- Industrial and food processing equipment exposed to acidic conditions

Standards

317L Stainless Steel

Carbon Content: ≤ 0.03%

Mechanical Properties

- tensile Strength:≈500 MPa

- yield Strength:≈190 MPa

- elongation:≈40%

- hardness:Approx. HRB 92

Key Features

- Lower carbon content for improved weldability

- Minimized risk of carbide precipitation in welded structures

- Delivers similar corrosion resistance and mechanical performance as 317

Common Applications

- Welded chemical processing systems

- Marine components and offshore installations

- Industrial equipment requiring extensive welding

- Architectural applications in corrosive environments

Standards

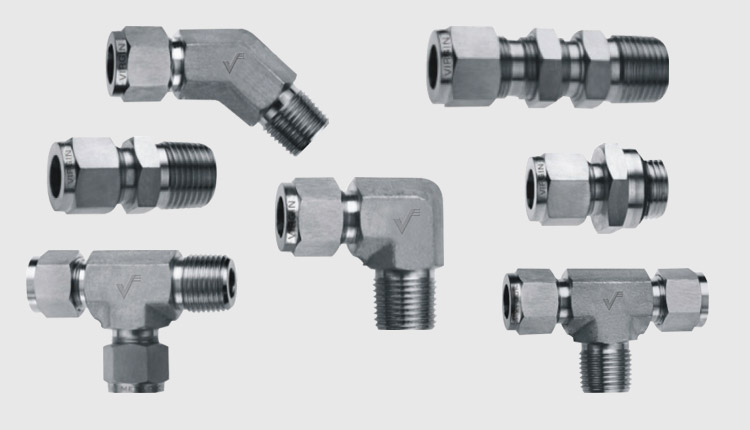

Products Available in 317/317L Stainless Steel

Products

Main Categories

Material Types

- Stainless Steel

- Inconel

- Incoloy

- Hastelloy

- Nickel Alloy

- Monel

- Titanium

- Cupro Nickel

Need 317/317L Stainless Steel Products?

Contact our experts today to discuss your specific requirements and get a customized quote for your project.