Extruded Steel Profile

Abhinav Overseas: Extruded Steel Profile Supplier & Stockist in India

Abhinav Overseas is a premier supplier and stockist of high-quality Extruded Steel Profiles in India. Our comprehensive range includes standard and custom profiles manufactured through precision hot extrusion processes.

The material used in our steel shape profiles includes both carbon steel and stainless steel variants, meeting diverse industrial requirements. We offer profiles in various grades including SS 304/304L, SS 316/316L, and carbon steel variants.

Extruded steel shapes provide significant advantages including reduction in machining needs, finishing requirements, and material waste. Our profiles feature excellent dimensional accuracy, superior surface finish, and consistent mechanical properties throughout the section.

The steel profiles are hot extruded to exact specifications, ensuring optimal performance in demanding applications across automotive, construction, and manufacturing industries.

With our extensive inventory and technical expertise, we can supply custom profiles with quick delivery timelines and competitive pricing. Our technical team can assist in selecting the right profile type and material grade for your specific application requirements.

Key Benefits

- Reduction in machining needs

- Reduced finishing requirements

- Minimized material scrap

- Precise section reproduction

- Smooth steel flow through the extruded shape die

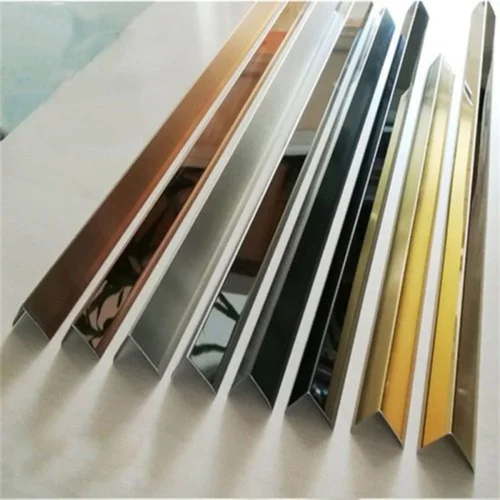

Extruded Steel Profile Types

T Profile

T-shaped profile commonly used in structural applications

L Profile (Angle)

L-shaped angle profile for joining and framing

U Profile (Channel)

U-shaped channel profile for support and containment

I Profile (Beam)

I-shaped beam profile for structural support

Z Profile

Z-shaped profile used in purlins and framing

Technical Specifications

| Specification | Details |

|---|---|

Shape & Profile Types | T-Profile, H-Profile, I-Beam, U-Channel, Angle Bar, Z-Profile, Custom Extruded Sections |

Size Range | Customized as per requirement, standard widths up to 500mm |

Thickness Range | 1mm to 100mm |

Length | Up to 6 meters or as per customer requirement |

Grades Available | SS 304, SS 304L, SS 316, SS 316L, SS 310, SS 321, SS 347, SS 409, SS 430, SS 446, SS 410, SS 420, SS 431, S31803, S32205, S32750, S32760 |

Manufacturing Process | Hot Extruded, Cold Drawn, Cold Rolled, Precision Machined |

Surface Finish | HRAP (Hot Rolled Annealed & Pickled), No.1, No.2B, No.4, BA (Bright Annealed), Mirror Finish, Brushed Finish |

Edge Condition | Sharp Edge, Rounded Edge, Smooth Machined Edge |

Tolerance | As per ASTM, ASME, EN, JIS, DIN, and other international standards |

Standards | ASTM: A276, A479; ASME: SA276, SA479; EN: EN 10088-2; JIS: JIS G4304, JIS G4305 |

Mechanical Properties | Yield Strength: As per Grade Specification, Tensile Strength: As per Grade Specification, Elongation: As per Standard |

Heat Treatment | Annealed & Pickled, Solution Annealed, Hardening & Tempering |

Inspection & Test Reports | Mill Test Certificates (MTC), EN 10204 3.1, PMI Test, Mechanical & Chemical Analysis Reports, Hardness Test, Ultrasonic Test, NABL Approved Lab Reports, Third-Party Inspection Reports |

Packing | Wooden Boxes, Wooden Pallets, Plastic Wrapping & Steel Strapped, As per Customer Requirement |

Special Requirements | Custom Sizes and Specifications available on request |

Applications

Design Considerations

- Facilitation of a smooth steel flow through the extruded shape die, Total avoidance of sharp edges

- Achieving precise section reproduction, define the rounded corners along with fillets

- For designing a groove, ratio of depth to width to be kept very low. A one-to-one ratio is to be maintained

- For accomplishing the desired non-symmetrical shape, all hole requirements is to be eliminated

Production Process

- Hot extrusion to required specifications

- Transportation via roller tables between workstations

- Cutting with shears on first roller table

- Finishing cuts with hot saw on second table

Products

Main Categories

Material Types

- Stainless Steel

- Inconel

- Incoloy

- Hastelloy

- Nickel Alloy

- Monel

- Titanium

- Cupro Nickel

Need Extruded Steel Profile?

Contact our experts today to discuss your specific requirements and get a customized quote for your project.

Request a Quote